Riding in July heat feels nothing like riding in January wind. Moreover, a quick hop at 15 mph (25 km/h) does not carry the same risks as a 35 mph (56 km/h) commute. Because both season and speed change the physics, protective gear by season and speed class must adapt. Consequently, this guide shows you how to choose, verify, and maintain seasonal riding gear that matches impact energy, slide time, weather, and visibility—without hype and without brands.

For a concrete Class 2 commuter example, see the Segway Ninebot F2, then use the Season × Speed Class matrices to dial in your kit.

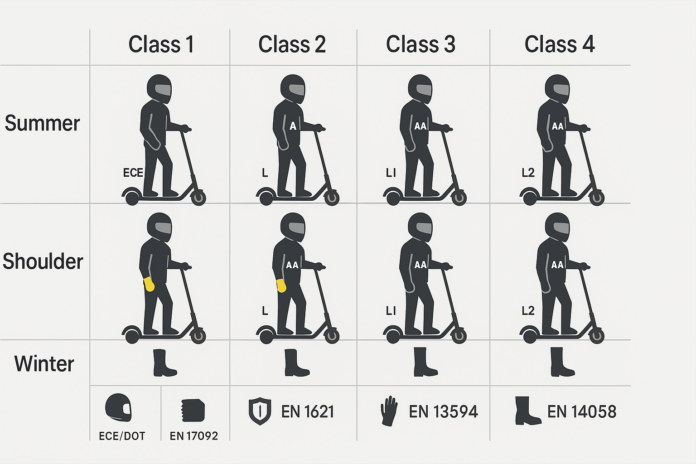

The Framework — Season × Speed Class

First, anchor your decisions in a simple grid: season on one axis and practical speed classes on the other. Then, align protection, climate control, and visibility to the cell you actually ride in.

Speed classes

- Class 1: up to ~15 mph (25 km/h)

- Class 2: ~16–25 mph (26–40 km/h)

- Class 3: ~26–35 mph (41–56 km/h)

- Class 4: 36+ mph (57+ km/h)

How risk scales with speed and weather

- Impact energy rises with speed. As a result, even small increases elevate crash forces, so helmet validation and armor level matter more at higher classes.

- Abrasion time grows with speed. Therefore, stronger textiles, reinforced zones, and robust seams become critical as you move up.

- Visibility drops in adverse weather. Rain, spray, low sun, and winter darkness reduce conspicuity; thus, reflective elements and rider-mounted lights help you stand out.

- Heat and cold change fit. In summer, sweat can let armor wander; conversely, winter bulk can restrict dexterity. Accordingly, layer to preserve fit and mobility.

Overall, think dynamically. If your speed or weather changes, your kit should change too.

Helmet Standards, Fit & Field Checks

ECE 22.06 vs DOT FMVSS 218

- ECE 22.06: This current European regulation broadens impact point selection, adds oblique (rotation-related) testing, and tightens requirements around visors and labeling. Consequently, it targets a wider range of real-world hits.

- DOT FMVSS 218: This US regulation sets minimum performance for impact attenuation, penetration, and retention, and it specifies labeling requirements. However, it relies on post-market enforcement and does not include a dedicated rotational test like ECE 22.06.

Bottom line: At higher speed classes, many riders favor helmets validated to comprehensive suites such as ECE 22.06, while maintaining DOT FMVSS 218 compliance where required. In any case, the best helmet is the one that fits correctly and stays stable through a crash.

Shell types, EPS, liner technologies; vents vs winter covers

- Shells: Thermoplastic, fiberglass composite, and carbon composite shells balance weight and stiffness differently. Notably, stiffer shells can spread loads, yet the EPS still handles deceleration.

- EPS liners: Single- or multi-density EPS crushes to absorb energy; multiple densities, therefore, help across impact ranges.

- Rotation management: Low-friction slip layers or engineered shear zones reduce rotational acceleration during oblique impacts. As a result, they can lower brain stress in certain crashes.

- Vent strategy: In summer, use intakes and exhausts liberally; in winter, close vents and add a chin curtain or breath guard to cut fogging and drafts. Additionally, consider a winter visor insert.

Field-verify labels, manufacture date, crash replacement rules

- ECE marking: Look for the circled E with a country code and an approval line including 22.06; typically, this is stitched to the strap. Furthermore, verify the type designation (e.g., P for a protective chin bar).

- DOT label caveats: A rear DOT mark is necessary for DOT helmets; however, counterfeits exist. Therefore, inspect construction quality, strap hardware, visor function, and documentation.

- Manufacture date: Find the date stamp on the label or liner. Because materials degrade with time, replace on a 5–7 year cycle even without a crash. After any impact that loads the shell or EPS, replace immediately.

Fit protocol (head shape, crown pressure, roll-off check, 15-minute comfort test)

- Head shape first: Identify round, intermediate oval, or long oval; then, match the shell to avoid hot spots.

- Crown pressure: Seek even contact; otherwise, try another size or shape.

- Cheek fit: Cheek pads should gently compress when you speak, yet they should not pinch.

- Roll-off test: With the strap snug, try to pull the helmet off forward and backward; it should not roll off the crown.

- Vision and rotation: Ensure you can shoulder-check without strain.

- 15-minute wear: Keep it on; comfort problems often appear late. Consequently, a patient test prevents buyer’s remorse.

Because stability depends on fit, this protocol directly supports protective gear by season and speed class across heat, wind, and winter layers.

Abrasion & Impact — Jackets, Pants, Armor

EN 17092 classes (A/AA/AAA) and zone mapping

- EN 17092 rates motorcycle garments for abrasion, seam burst, tear resistance, and coverage.

- A: Urban speeds; lighter builds and shorter slide times.

- AA: Balanced protection for general road speeds.

- AAA: Highest level; extended slide times and stronger construction.

- Zones (simplified):

- Zone 1 (high risk): Shoulders, elbows, outer forearms, hips, knees, and seat; therefore, demand the strongest materials and backing.

- Zone 2 (medium): Upper arms, thighs, chest, and lower legs; still needs good abrasion and seams.

- Zone 3 (low): Remaining areas; nonetheless, they must hold the garment together.

As you climb classes, move from A → AA → AAA, especially for Zone 1.

Armor standards: EN 1621-1 (limbs) & EN 1621-2 (back)

- EN 1621-1 (limbs): Shoulder, elbow, hip, and knee armor in Level 1 or Level 2; Level 2 allows less force through. Consequently, it’s preferable at higher speeds.

- EN 1621-2 (back): Back protectors also come in Level 1 or Level 2; longer profiles increase tailbone coverage.

- Fit and placement: Armor must sit on the joint in riding posture. Therefore, use adjustable pockets and straps to lock position. Replace thin foam with certified armor.

Materials overview

- Leather: Predictable slides and strong abrasion; however, you will need ventilation or layers for temperature control.

- High-denier textiles: 500D–1000D polyamide balances weight and durability; additionally, look for double layers in Zone 1.

- Aramid reinforcements: Para-aramid panels add heat and cut resistance at elbows, shoulders, hips, and knees.

- UHMWPE blends: High strength-to-weight and cool touch; often blended with nylon for durability.

- Seams: Double or triple lockstitch reduces burst risk; moreover, protected external seams resist direct abrasion.

Gloves, Boots & Contact Points

EN 13594 gloves

- Levels: Level 1 and Level 2 thresholds for impact and abrasion; Level 2 increases margin at speed.

- Knuckles: Hard or energy-absorbing shells reduce direct blows.

- Palm sliders: Low-friction components help the hand slide rather than grab, which therefore protects the wrist.

- Cuffs: Short cuffs suit heat and Class 1–2; gauntlets overlap sleeves for weather sealing and coverage, especially in Class 3–4.

EN 13634 boots

- Core features: A midfoot shank, firm ankle cups, and a grippy sole that works when wet.

- Height: Mid cuffs are versatile across seasons; high cuffs block rain and stabilize ankles in winter.

- Fit: Toes should wiggle while the heel locks. Additionally, walk a few minutes to confirm comfort.

Hands and feet control braking, balance, and stance; consequently, they anchor protective gear by season and speed class.

Weatherproofing, Thermal & Visibility Layers

Waterproofing and breathability (EN 343)

- Membranes: PU and PTFE membranes block liquid water while passing vapor; hence, they keep you drier over long rides.

- DWR: A Durable Water Repellent on the face fabric sheds droplets; when water stops beading, re-proof it.

- Seam sealing: Taped seams prevent leaks at stitch lines.

- EN 343: This standard categorizes rain protection and breathability, which helps you compare rain gear consistently.

Thermal management (EN 14058 for cool environments)

- Base layers: Synthetics or merino wick sweat; by contrast, cotton traps moisture.

- Mid layers: Fleece or insulated liners trap warm air without bulk.

- Shell: Windproof outers reduce convective loss dramatically.

- EN 14058: This standard addresses cool environments, so it informs expectations for light-cold garments.

- Wind-chill: Because speed multiplies heat loss, dress warmer than the thermometer suggests.

Visibility

- Retro-reflective placements: Put reflective on moving parts—wrists, elbows, and ankles—to create motion cues.

- Color blocks: High-contrast panels increase daytime conspicuity.

- Active lighting: Clip-on lights or fiber strips mounted on the rider cut through spray, dusk, and glare.

Seasonal Setups (with Speed-Class Tuning)

Use the matrices below to translate conditions into gear choices. Importantly, adjust one step up or down if your route or exposure changes.

Summer (hot to very hot)

| Speed Class | Helmet & Visors | Jacket / Pants (EN 17092) + Armor | Gloves (EN 13594) | Boots (EN 13634) | Weather Strategy | Visibility Add-ons |

|---|---|---|---|---|---|---|

| Class 1 | Light full-face or open-face, ECE 22.06 or DOT FMVSS 218; clear visor plus internal tint | A class mesh/perf textile with reinforced Zone 1; Level 1 limbs; back Level 1 | Level 1 short cuff, ventilated, palm slider preferred | Mid-height, grippy sole | Maximize venting; hydrate; manage sunscreen | Retro on wrists/ankles; small rider light |

| Class 2 | Full-face with strong venting and anti-fog | AA mesh/textile with double layers at elbows/shoulders/seat; L1–L2 limbs; back L1 | L1–L2 short or mid cuff with slider | Mid cuff with ankle reinforcement | Open chest/back vents; moisture-wicking base | High-contrast blocks; reflective tape on pack |

| Class 3 | Full-face with rotation management; clear visor + drop-down tint | AA–AAA vented textile or perforated leather; L2 limbs; back L2 | L2 short cuff with slider; gauntlet optional | Mid or high cuff, shank recommended | Use thigh and bicep vents; stabilize armor straps | Active rider rear light; reflective bands |

| Class 4 | Full-face, ECE 22.06; robust chin bar; rotation management | AAA with strong Zone 1 reinforcements; L2 limbs + optional chest | L2 gauntlet with slider | High cuff with stiff shank | Control airflow; minimize flap; secure cuffs | Multiple rider lights; high-contrast panels |

Shoulder Seasons (cool mornings, variable rain)

| Speed Class | Helmet & Visors | Jacket / Pants (EN 17092) + Armor | Gloves (EN 13594) | Boots (EN 13634) | Weather Strategy | Visibility Add-ons |

|---|---|---|---|---|---|---|

| Class 1 | Full-face or modular; clear visor with anti-fog | A–AA textile with removable liner; L1 limbs; back L1 | L1 mid cuff with light insulation | Mid cuff; basic waterproofing | Carry rain layer; close top vents; thin base | Reflective piping; ankle bands |

| Class 2 | Full-face with chin curtain; pinlock-style anti-fog | AA seam-sealed textile; L1–L2 limbs; back L1–L2 | L1–L2 mid cuff with visor wiper | Mid or high cuff; better tread | Laminated shell or over-jacket; wicking base + light fleece | High-contrast blocks; clip-on red light |

| Class 3 | Full-face with breath guard; rotation management | AA–AAA laminated textile; L2 limbs; back L2 | L2 gauntlet, light insulation, wiper | High cuff; good shank; heel/toe cups | Windproof chest; seal collar; over-mitts for downpours | Reflective on shoulders/back; active light |

| Class 4 | Full-face, ECE 22.06; robust sealing | AAA laminated with storm cuffs; L2 limbs + chest | L2 gauntlet; rain-ready | High cuff with gaiter; deep tread | Base + mid layers; controlled venting to prevent sweat | Red and amber rider lights; reflective ankles/wrists |

Winter (cold, dark, wet or icy)

| Speed Class | Helmet & Visors | Jacket / Pants (EN 17092) + Armor | Gloves (EN 13594) | Boots (EN 13634) | Weather Strategy | Visibility Add-ons |

|---|---|---|---|---|---|---|

| Class 1 | Full-face with winter breath guard; clear visor | AA insulated textile; L1–L2 limbs; back L1 | L1–L2 insulated mid cuff; good control feel | Mid/high cuff; warm insole | EN 14058-style layering; seal cuffs/collar | Reflective sash; ankle lights |

| Class 2 | Full-face with chin curtain; anti-fog insert | AA–AAA insulated or laminated; L2 limbs; back L2 | L2 insulated gauntlet; visor wiper blade | High cuff; waterproof gaiter | Windproof mid layer; heated grips/gloves optional | Active front/rear lights; bright blocks |

| Class 3 | Full-face with rotation management; dual-pane anti-fog | AAA laminated; storm flaps; L2 limbs + chest | L2 insulated gauntlet with slider | High cuff; aggressive tread | Plan for wind-chill; regulate sweat; heated mid layer | Multiple rider lights; color blocks |

| Class 4 | Full-face, ECE 22.06; sealed; electric visor if available | AAA laminated, long hem; L2 all around | L2 insulated gauntlet; over-mitts for heavy rain | High cuff with stiff shank; ice-friendly tread | Heat plus moisture control: breathable base + regulated heat | Large reflectives; steady + flashing rider lights |

Because these tables translate conditions into concrete choices, they make protective gear by season and speed class easy to apply before every ride.

Decision Flows & Fit Procedures

Flow: weather and speed → gear

- Pick today’s top speed.

- ≤15 mph → start at A + Level 1.

- 16–25 mph → AA + Level 1–2.

- 26–35 mph → AA/AAA + Level 2.

- 36+ mph → AAA + Level 2 everywhere.

- Choose the weather lane.

- Hot/dry: Ventilate, yet reinforce Zone 1.

- Cool/variable: Add laminated shells or packable rain.

- Cold/wet/dark: Seal cuffs, insulate, and add rider lighting.

- Confirm helmet validation.

- Prefer ECE 22.06 for broader testing; keep DOT FMVSS 218 where required.

- Lock armor on joints.

- Adjust pockets and straps; otherwise, size for better alignment.

- Match gloves and boots.

- Select EN 13594 level and cuff length, plus EN 13634 boots with a shank.

- Add visibility.

- Put reflective on moving parts and mount an active rear light on the rider.

If a box fails, reduce speed or delay the ride; safety, therefore, remains the priority.

Fit procedures (quick but thorough)

Helmet

- Snug strap; pass the two-finger check.

- Roll-off test both directions; the helmet stays put.

- Shoulder checks are easy; no visor fogging.

- After 15 minutes, no hot spots appear.

Jacket and pants

- In riding posture, armor centers on shoulders, elbows, hips, and knees.

- Sleeves cover wrist bones; pants cover ankles while seated.

- Cuffs and hems seal; no flapping at speed.

- Waist and limb adjusters keep armor stable.

Gloves

- Fingers bend without pressure; levers are easy to reach.

- Palm slider sits at the heel; seams feel smooth.

- Gauntlets overlap sleeves in rain or winter.

Boots

- Heel locked; toes can wiggle.

- Ankle support feels firm; sole grips wet tile.

- Laces or buckles tidy and away from the drivetrain.

Verification & Avoiding Counterfeits

- Label logic: Confirm the stitched ECE 22.06 label with proper format and type code. For DOT FMVSS 218, verify the sticker and scrutinize construction and documentation.

- Build quality: Even stitching, clean seam tape, solid bar-tacks, and tidy edges indicate care; by contrast, ragged stitching and sharp plastics are red flags.

- Armor stamps: Look for EN 1621-1/-2 and the Level marking molded into protectors.

- Claims vs details: Be skeptical of vague terms like “race grade” without the actual standard.

- Packaging sanity: Reasonable manuals, batch codes, and consistent printing suggest authenticity.

Care, Maintenance & Replacement

- Helmet: Use mild soap; avoid solvents. Replace after any crash or when the shell/EPS shows damage. Additionally, plan time-based replacement every 5–7 years.

- Textiles: Close zips; wash with technical cleaner; then, re-proof DWR when water no longer beads.

- Leather: Clean and condition; dry slowly, away from heat sources.

- Armor: Remove before washing; replace if deformed, torn, or hardened.

- Gloves/boots: Air dry; refresh insoles; maintain seam sealing.

- Closures: Lubricate zippers lightly; replace broken snaps early.

Because routine care preserves performance, these simple steps extend gear life across seasons.

Budget Tiers Without Compromise

Class 1 (urban)

Invest first in helmet fit and glove quality (with palm sliders). An A class jacket and pants with Level 1 armor can suffice for short trips. However, do not skip ankle protection.

Class 2 (suburban)

Upgrade to AA garments, improve back protection, and step into sturdier EN 13634 boots. Additionally, refine visibility with reflective placements.

Class 3 (arterials)

Choose Level 2 armor and AA/AAA shells. Prefer helmets with rotation management and reliable anti-fog. Furthermore, stabilize armor with straps.

Class 4 (high-speed segments)

Commit to AAA garments and Level 2 armor everywhere. Select an ECE 22.06 full-face with robust retention and sealing. Finally, build a conspicuity system: reflective on moving parts plus rider-mounted lights.

Across tiers, save on graphics and gadgets, not on recognized standards, coverage, or fit.

Myths vs Facts

- Myth: “DOT is automatically safer than ECE.”

Fact: DOT FMVSS 218 sets US minimums, whereas ECE 22.06 adds broader impact locations and oblique testing. Therefore, validation scope differs; fit still rules safety outcomes. - Myth: “Mesh equals no protection.”

Fact: Many EN 17092 A/AA garments use mesh intelligently with reinforced Zone 1 panels and real armor. Consequently, design, not mesh alone, decides protection. - Myth: “AAA garments remove the need for Level 2 armor.”

Fact: EN 1621 Level 2 reduces transmitted force. Thus, armor level still matters even inside AAA shells. - Myth: “Any waterproof jacket works in winter.”

Fact: Breathability and seam sealing drive comfort and safety. Therefore, look for EN 343-style performance and pair it with EN 14058-appropriate layering. - Myth: “Thicker gloves are always safer.”

Fact: You also need lever feel. As a result, pick EN 13594 gloves that protect and preserve control.

Quick Reference

Minimum standards by speed class (dry conditions)

| Speed Class | Helmet | Jacket/Pants | Limb Armor | Back Armor | Gloves | Boots |

|---|---|---|---|---|---|---|

| Class 1 | ECE 22.06 or DOT FMVSS 218 | A (reinforced Zone 1) | EN 1621-1 L1 | EN 1621-2 L1 | EN 13594 L1 | EN 13634 |

| Class 2 | ECE 22.06 preferred | AA | EN 1621-1 L1–L2 | EN 1621-2 L1–L2 | EN 13594 L1–L2 | EN 13634 (mid/high) |

| Class 3 | ECE 22.06 + rotation management | AA–AAA | EN 1621-1 L2 | EN 1621-2 L2 | EN 13594 L2 | EN 13634 (high) |

| Class 4 | ECE 22.06 full-face | AAA | EN 1621-1 L2 | EN 1621-2 L2 | EN 13594 L2 | EN 13634 (stiff shank) |

Season × Speed class × Minimums (wet or cold add-ons)

| Season | Class 1 | Class 2 | Class 3 | Class 4 |

|---|---|---|---|---|

| Summer | A + L1; mesh with reinforced zones; short-cuff gloves | AA + L1–L2; vented; short/mid gloves | AA/AAA + L2; vented; consider gauntlet | AAA + L2; vented AAA; gauntlet |

| Shoulder | A/AA + L1; packable rain | AA + L1–L2; laminated or liner | AA/AAA + L2; laminated | AAA + L2; laminated; storm cuffs |

| Winter | AA + L1–L2; insulated; mid boots | AA/AAA + L2; insulated; mid/high boots | AAA + L2; insulated; high boots | AAA + L2; insulated; high boots; heated options |

(L1/L2 = armor levels under EN 1621.)

Pre-ride gear checklist

- Helmet strap snug; visor clean; vents set for weather.

- Armor aligned at shoulders, elbows, hips, and knees in riding posture.

- Zips closed; cuffs sealed; pants secure at the waist.

- Glove feel confirmed; no fingertip pressure at full fist.

- Boots locked at the heel; soles grip when wet.

- Reflective visible from the rear; rider light on.

- Vents open or rain shell packed, depending on forecast.

Seasonal changeover checklist

- Wash technical shells; then re-proof DWR.

- Inspect seam tape for peeling; repair early.

- Swap to Level 2 armor for higher-speed winter routes.

- Test heated gear; confirm battery health and cable strain relief.

- Replace anti-fog inserts or reapply treatment.

- Refresh reflectives; replace worn ankle/wrist bands.

Because these lists are short and direct, they encourage consistent habits.

Safety & Legal Note

This guide is educational and references official standards only: ECE 22.06, DOT FMVSS 218, EN 17092, EN 1621-1/-2, EN 13594, EN 13634, EN 343, and EN 14058. However, local laws vary. Therefore, obey regulations, ride within conditions, and use judgment.

Glossary

- ECE 22.06: European helmet regulation with expanded impact and oblique testing.

- DOT FMVSS 218: US helmet regulation specifying impact, penetration, retention, and labeling.

- EN 17092 (A/AA/AAA): Garment standard for abrasion, seam strength, tear resistance, and coverage.

- EN 1621-1: Limb armor standard; Level 2 transmits less force than Level 1.

- EN 1621-2: Back protector standard with Level 1 and Level 2 limits.

- EN 13594: Motorcycle glove standard addressing impact, abrasion, and seams.

- EN 13634: Boot standard for impact protection, shank stiffness, and sole grip.

- EN 343: Protective clothing standard for rain resistance and breathability.

- EN 14058: Garment standard for cool environments.

- Zone 1/2/3: Construction zones indicating high/medium/low contact risk.

- DWR: Durable Water Repellent finish that restores water beading.

- Laminated shell: Membrane bonded to outer fabric for quick drying and lighter feel.

- Palm slider: Low-friction insert that reduces wrist-twist during slides.

- Shank: Stiffener in boot soles that protects the midfoot.