A solid fold is more than convenience. Instead, it is core to safety and ride feel. When the hinge is tight, the scooter tracks straight and brakes with confidence. Conversely, when it is loose, wobble grows and parts wear fast. Therefore, this guide puts folding mechanisms compared in plain language so you can ride with confidence.

Why Folding Design Matters

To begin, the fold sits between you and the road. It carries steering, braking, and rider weight. Therefore, any play at the hinge shows up as bar shake, especially under front braking. Even a small gap can feel big at speed.

Moreover, good design spreads load across wide clamp faces and stable pivots. Additionally, it keeps shape through heat, rain, and daily folds. As a result, the chassis stays quiet and parts last longer. In contrast, a loose hinge speeds up wear. Pins oval out, latch faces deform, and bolts stretch. Consequently, hinge quality sets stability, braking feel, and long-term durability. Above all, a well-set hinge protects you when you brake hard.

Overview of Folding Architectures

First, here are the most common types. For clarity, each entry includes “diagram-ready” notes. Additionally, each note explains why the design matters in practice.

- Collar clamp (split clamp) hinges

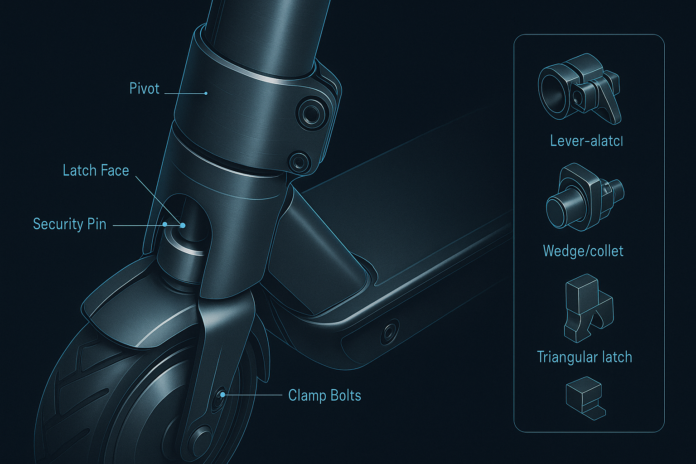

Diagram: Show a stem base with a split collar. Two or four bolts pinch the split. A hinge knuckle sits ahead of the collar. Label the split, bolts, knuckle, and stop face.

Why it matters: Clamp width and even bolt load control rocking. Furthermore, wider faces reduce local stress. - Lever-latch with safety pin/tab

Diagram: Show a cam lever pulling a latch face to a plate. A cross-hole takes a spring pin or flip tab as backup. Label the cam lever, latch face, plate, and pin.

Why it matters: Small cam wear changes preload fast. Consequently, lever feel can drift week to week. - Wedge/collet expanding joints

Diagram: Show a conical wedge pulled by a bolt into a split sleeve (collet). The sleeve expands into a socket. Label the cone, collet, draw bolt, and seat angle.

Why it matters: The wedge self-centers and can kill micro-play. However, it demands clean surfaces and correct torque. - Multi-bolt stem clamps (BMX-style doubles)

Diagram: Show two separate clamps stacked on the lower stem. Each clamp has two bolts. Label the upper clamp, lower clamp, width, and bolt spacing.

Why it matters: Wider faces and more bolts boost stiffness. Nevertheless, torque must be even across all bolts. - Threaded/triangular latch systems

Diagram: Show a triangular block that rotates into a pocket. A threaded adjuster sets preload. Label the block, pocket, adjuster, and stop faces.

Why it matters: Three faces locate well. Yet, once gaps appear, edges round fast. - One-step “auto” latches with secondary safeties

Diagram: Show a spring hook that snaps over a catch as the stem rises. A slider or pin releases it. Label the hook, spring pack, slider, and over-center stop.

Why it matters: The snap is quick and tidy. Even so, it can hide poor seating unless you verify engagement.

Anatomy of a Fold Joint (Plain English)

- Hinge knuckle: The block with the pivot bore.

- Pivot pin/bolt: The axle for the fold.

- Bushings/shims: Thin parts that control side play.

- Latch surface: The face that holds the stem upright.

- Security pin/tab: The backup that blocks opening.

- Clamp bolts: The screws that create preload.

- Stop surfaces: The faces that define “fully open.”

In short, think of a door with a deadbolt plus a draw latch. Accordingly, everything must seat flat and tight. Otherwise, it will move and grow noisy.

What Fails First (and Why)

- Material wear: Tiny motions polish latch faces and round edges. Then friction drops and play grows.

- Bushing compression: Soft shims crush over time. Consequently, side play increases and lever feel lightens.

- Bolt stretch/loosening: Loads and vibration lengthen fasteners a hair. Without proper thread care, they back out.

- Latch face deformation: Contact stress peens the edge. A lip forms and blocks flush seating. As a result, clicks appear under braking.

- Pin shear: A small pin is a backup, not a main load path. If it holds primary load, it can shear.

- Tolerance stack: Small size errors add up. After many cycles, gaps show and wobble starts.

- Heat and vibration: Heat softens some plastics. Meanwhile, rough roads shake parts loose.

- Rider weight and style: Heavier riders and hard braking add hinge load. Therefore, wear arrives sooner.

- Repeated folding: Each fold risks mis-seat, cam wear, and lost preload. Eventually, play returns.

Accordingly, know these paths and set up service to block them before they snowball.

Mechanism-by-Mechanism Comparison (folding mechanisms compared)

Here is how each type works, where it shines, where it fails, what it needs, and what users often get wrong. Moreover, use this section to plan checks and spares.

Collar Clamp (Split Clamp) Hinges

- How it works: A split collar wraps the stem base. Bolts squeeze the split. The stem seats against the stop.

- Strengths: Simple and light. Moreover, wide collars spread load. Adjustments are easy and repeatable.

- Weak points: Narrow collars indent stems. Thin collars spring open. Threads strip if over-torqued.

- Maintenance need: Medium. Keep faces clean and bolts even. Re-torque on schedule.

- User errors: Oily faces, uneven bolt load, and low torque. Consequently, rocking and squeaks develop quickly.

Lever-Latch with Safety Pin/Tab

- How it works: A cam lever pulls the latch face tight. A pin or tab blocks release.

- Strengths: Fast to use. Additionally, the backup lock is clear and simple.

- Weak points: Cam noses wear. Latch plates peen. Pins bend if used as primary load parts.

- Maintenance need: Medium to high. Inspect cam and plate. Replace worn parts.

- User errors: Closing without full seating. Ignoring a lever that got “too easy.” Riding without the pin clip. Therefore, verify closure every ride.

Wedge/Collet Expanding Joints

- How it works: A wedge pulls into a split sleeve. The sleeve expands to lock in a socket.

- Strengths: Strong axial grip and great self-centering. Consequently, micro-play is very low when set right.

- Weak points: Dry, dirty wedges can gall. Over-tightening can crack the collet.

- Maintenance need: High. Clean contact faces matter. Correct torque matters.

- User errors: Grit in the taper. Mixing lube and threadlocker. Over-torque on the draw bolt. As a result, release can stick and faces can score.

Multi-Bolt Stem Clamps (BMX-Style Doubles)

- How it works: Two stacked clamps grip the stem. Four bolts set even preload.

- Strengths: Stiff and redundant. Therefore, it suits heavier riders and higher speed.

- Weak points: More bolts to check. Narrow clamps can bite soft stems.

- Maintenance need: Medium. Use even torque and clean faces.

- User errors: Tightening one side only. Mixing bolt lengths. Ignoring clamp width vs stem wall. Consequently, drift appears after bumps.

Threaded/Triangular Latch Systems

- How it works: A triangle block rotates into a pocket. A threaded part sets the squeeze.

- Strengths: Three faces give positive location. Thus, off-axis wobble is controlled.

- Weak points: Adjusters can loosen. Loose edges round fast under impact.

- Maintenance need: Medium to high. Keep faces clean. Set the adjuster right.

- User errors: Too tight (binds). Too loose (chatters). Not re-setting after bushing changes. Therefore, watch for notch feel and correct early.

One-Step “Auto” Latches with Secondary Safeties

- How it works: The stem swings up. A spring hook snaps over a catch. A slider or pin must release for folding.

- Strengths: Very quick. Meanwhile, it promotes repeatable closure.

- Weak points: Springs can tire. Hooks can wear. The snap can hide poor seating.

- Maintenance need: High. Clean and test springs and hooks.

- User errors: Trusting the snap without a visual check. Riding with a sticky slider. Forcing closure while misaligned. Consequently, hooks may round or bind.

Real-World Symptoms of a Problem

- Click under braking: A face or pivot shifts forward, then snaps back. Therefore, seating is not flush.

- Bar shake at speed: Hinge play couples with tire runout. Consequently, wobble grows with speed.

- Visible gap at the hinge: Light shows where faces should meet.

- Lever closes too easily: Cam wear or missing shims reduce preload.

- Uneven marks: Bright spots on an edge show misalignment.

- Persistent rattle: Compressed bushings or stretched bolts.

- Lever bounce: The cam is not over-center. Spring tension may be low.

- Pin hard to insert: Parts are misaligned or the pin is bent. As a result, the lock becomes unreliable.

Accordingly, treat these as early warnings and fix them before damage spreads.

Set-Up & Adjustment Basics (Safety First)

- Inspect: First, clean faces, pivots, and clamps. Look for burrs or dents. If the manual calls for dry, keep latch faces dry.

- Seat parts: Next, assemble dry or with a thin film if the manual allows it. Most latch faces should be clean and dry.

- Preload: Then, tighten bolts in a cross pattern. Use small steps. Snap cams over-center with firm hand force.

- Thread care: Additionally, use medium threadlocker only where the manual says. Use anti-seize only where called for. Never mix both on one thread.

- Torque: Likewise, follow the manual for torque and order. Do not guess or “feel.”

- Short ride re-check: After 5–10 miles, re-check bolt torque, lever feel, and seating marks. Then, note results in a simple log.

- After transport: Furthermore, racks and straps can change preload. Therefore, check before you ride again.

- Replace hardware on schedule: Finally, if the manual lists life limits for pins or bolts, follow them. Consequently, failures stay rare.

Maintenance Intervals & Checklists

- Pre-ride (10–20 seconds):

First, close the latch and confirm a flush seat. Next, ensure the backup pin is engaged. Then, hold the front brake and tug the bars. Feel for clicks. Finally, check bolt heads. They should sit flush and even. - Weekly deep check:

First, verify torque on clamp bolts. Then, inspect latch faces for bright lips. Next, check pivot pin tightness or clip fit. Lastly, test the backup pin or slider. - Monthly/seasonal service:

If design allows, remove the pivot. Then clean bushings and check shims. Replace crushed parts. In addition, look for oval holes. Replace stretched or rusty bolts. Finally, keep a short log to spot trends.

As a result, consistency keeps the hinge quiet and tight. Moreover, logs make patterns obvious over time.

Additionally, for a model-specific walk-through that illustrates many of these checks, see the Segway Ninebot MAX G30/G2/G3 care, common fixes & best add-ons guide.

Security Pins & Secondary Safeties

A secondary lock is your last line. It does not hold main load when the latch is right. Yet it stops accidental opening. A good pin fits snug without force. The retainer spring or clip must be intact. If the pin bends or the tab cracks, replace it at once.

If you ignore it:

- The lever can bounce open after a pothole.

- A half-seated pin can shear.

- A cracked tab can tear and fail to block motion.

Accordingly, use the secondary device every time. In practice, it takes seconds and prevents big problems.

Clamps, Bolts & Materials

- Bolt grades: Use the grade the manual lists. It sets stretch, torque, and clamp life. Otherwise, readings mislead and threads suffer.

- Clamp width: Wider clamps spread load and resist rocking. Conversely, narrow clamps mark stems and move more.

- Lever cam wear: Cams are tiny wedges. As they polish, lift drops. Therefore, a lever that once needed a firm palm may now close with two fingers. Service it.

- Aluminum vs steel: Aluminum clamps are light but can cold-flow. Steel sleeves help. Meanwhile, dry stainless into aluminum can gall and seize. Therefore, follow guidance and use the right compound.

Taken together, the right parts—set right—extend hinge life by a lot. Furthermore, they keep ride feel crisp and predictable.

Testing Protocol: Prove Your Fold Is Solid (10-Minute Loop)

Station 1: Hard-brake test

First, find a safe, empty spot. Roll at 8–10 mph. Then squeeze the front brake firmly. Listen for a click. If you feel movement, stop and inspect.

Station 2: Low-speed slalom

Next, weave at walking speed. A good hinge tracks clean with no delay. However, any knock or notch means play.

Station 3: Rough asphalt chatter

Then ride a coarse patch while light on the deck. A solid hinge stays quiet. If you hear a rattle, suspect bolt stretch or crushed shims.

Station 4: Standing sprint and decel

Finally, accelerate hard, then slow. Load reversals expose slack. If the lever pulses, the cam is not over-center.

Pass feel:

No clicks. No rattle. Lever stable. Steering neutral. Therefore, if you hear snaps, see gaps, or feel lever movement, stop and adjust.

Portability vs Rigidity Trade-Offs

On one hand, one-step latches win for speed. They suit daily fold and carry. On the other hand, multi-bolt systems win for stiffness. They suit heavier riders and higher speeds. Likewise, off-road use prefers wider clamps or wedges that hold firm. Meanwhile, city riders prefer quick, repeatable closure. Consequently, choose what fits your routine and weight. Then maintain it as a critical part of your scooter.

Troubleshooting Play & Rattle (Decision Tree)

- Lever closes too easily →

Cause: Cam wear or lost shims.

Action: Raise preload or add the right shim. Then inspect the cam nose for rounding. - Click only under braking →

Cause: Peened latch face or pivot slop.

Action: Dress raised lips only if allowed. Or replace the plate. Next, check the pivot fit. - Constant rattle →

Cause: Stretched bolts or crushed bushings.

Action: Re-torque and replace bolts. Then fit new bushings to restore preload. - Pin hard to insert →

Cause: Misalignment or bent pin.

Action: Do not force it. Instead, realign and replace the pin promptly. - Stem drifts off-center →

Cause: Dirty faces or low torque.

Action: Clean, dry, and re-torque in a cross pattern. - Re-shim or replace?

If play returns fast, hard parts are likely deformed. Therefore, replace the latch, wedge, or clamps. Re-shim only when faces are sound and square.

Buying Checklist (Folding Quality)

Before you buy, ask these. Additionally, try the 10-minute loop if possible.

- Clamp width: Are faces wide relative to stem size?

- Secondary lock: Pin, slider, or tab—and is it easy to inspect?

- Service access: Can you pull the pivot and reach shims?

- Spare parts: Are plates, cams, pins, and bushings available?

- Adjustment points: Is cam or wedge preload adjustable?

- Material pairing: Any steel sleeves against aluminum?

- On-road feel: Can you test ride briefly and check for play?

- Weight/purpose fit: Heavier or faster use needs stiffer designs.

- Manual clarity: Are torque and service steps clearly listed?

Altogether, this is folding mechanisms compared in practice. Pick a design that fits your needs and that you can service. Moreover, confirm parts support before you commit.

FAQs

How tight is “too tight” for a cam lever?

Tight is right with a firm palm snap over-center. If you need body weight or tools, it is too tight.

How often should I re-torque clamp bolts?

Check weekly at first. Then move to monthly once it holds steady. Always re-check after impacts or long trips.

Can I ride with slight play?

No. Even small play hammers the latch and grows fast. Therefore, fix it first.

What does “folding mechanisms compared” mean for me?

It means you check clamp width, the backup lock, service access, and parts support. Not just fold speed.

Do airlines allow folded scooters?

Rules vary. Folding helps with size. However, battery and dimension limits still apply.

Should I store folded or unfolded?

Either is fine if you relax the cam. Do not leave high preload for weeks.

When should I replace bushings or shims?

Replace them if normal adjustment cannot remove play. Also replace them if you see crush marks.

Is threadlocker always needed?

No. Use it only where the manual says. Some parts need dry threads or anti-seize.

Why does my lever feel different in heat?

Heat changes material and lube. Consequently, re-check after hot days or season changes.

Glossary

- Hinge knuckle: The block that holds the pivot bore.

- Pivot pin: The axle the joint rotates on.

- Cam: A curved lever that creates clamp force.

- Wedge: A cone that expands a sleeve.

- Collet: A split sleeve that expands to grip.

- Bushing: A sleeve that reduces wear and play.

- Shim: A thin spacer for fine fit.

- Threadlocker: A compound that stops bolts from backing out.

- Preload: Clamp force set before riding loads.

- Secondary lock: The backup that blocks opening.

- Tolerance stack: Small size errors that add up.

- Shear: A sliding force that cuts across a part.

- Galling: Metal surfaces tear and stick under pressure.

- Over-center: Lever position that locks against opening.

- Peening: Small impacts that deform a surface.

Printable Inspection Checklist

Use this before commutes and after transport. Because it is short, you will actually do it.

- Seat check: Latch faces touch with no gap.

- Backup on: Pin or slider engaged and held.

- Lever feel: Firm snap over-center. No bounce.

- Bolt heads: All flush and even.

- Pivot area: Clips present. No shiny burrs.

- Bar tug: Hold front brake. Pull bars. No click.

- Side shake: Rock the bars. No rattle.

- Sound check: Roll over a seam. Hinge stays quiet.

- Track straight: Bars and wheel align after bumps.

- Log: Note any change. Plan your weekly check.

Table 1: Folding Type vs Strengths, Weak Points, Maintenance Sensitivity, Typical Symptoms

| Folding Type | Strengths | Weak Points | Maintenance Sensitivity | Typical Symptoms |

|---|---|---|---|---|

| Collar clamp (split) | Simple, light, easy to adjust | Thread strip, collar spring-open, stem indenting | Medium | Squeaks, slow rocking growth |

| Lever-latch + pin | Fast closure, clear backup lock | Cam wear, plate peening, bent pins | Medium-High | Easy lever close, click on brake |

| Wedge/collet | Self-centering, strong axial grip | Galling, collet cracking | High | Creak under load, sticky release |

| Multi-bolt clamps | Very stiff, redundant | More bolts to check, stem bite | Medium | Off-center drift if uneven torque |

| Threaded/triangular | Positive three-face location | Loose adjuster, edge rounding | Medium-High | Notch feel, chatter on decel |

| One-step “auto” | Very quick, commuter friendly | Spring fatigue, hook wear | High | Snap without full seat, slider stick |

Table 2: Symptom → Likely Cause → Quick Action → Long-Term Fix

| Symptom | Likely Cause | Quick Action | Long-Term Fix |

|---|---|---|---|

| Click under braking | Peened latch or pivot slop | Reseat; tighten; inspect | Replace plate or bushings |

| Lever too easy | Cam wear or lost shim | Raise preload; add shim | Replace cam or shim set |

| Constant rattle | Bolt stretch or crushed bushing | Re-torque; replace bolts | Fit new bushings; wider clamp if needed |

| Pin hard to insert | Misalignment or bent pin | Realign; replace pin | Inspect stops; correct deformation |

| Bars off-center | Uneven clamp torque | Loosen; re-torque cross pattern | Dress faces; inspect stem wall |

| Sticking release | Galling in wedge/collet | Clean; lube if allowed | Replace wedge/collet; follow torque |

| Lever bounce | Not over-center | Adjust cam; verify stop | Replace spring or cam parts |

Table 3: Inspection Interval Guide (Pre-ride / Weekly / Monthly)

| Task | Pre-ride | Weekly | Monthly/Seasonal |

|---|---|---|---|

| Visual seat and gap | ✓ | ✓ | ✓ |

| Pin/tab function | ✓ | ✓ | ✓ |

| Bar tug & side shake | ✓ | ✓ | ✓ |

| Clamp bolt torque | ✓ | ✓ | |

| Cam/lever wear | ✓ | ✓ | |

| Pivot pin/clip | ✓ | ✓ | |

| Bushing/shim check | ✓ | ||

| Clean contact faces | ✓ | ✓ | |

| Replace worn hardware | ✓ |

Putting It All Together

In summary, keep folding mechanisms compared in mind as you choose and maintain a scooter. Commuters need speed and repeatable closure. Meanwhile, performance riders and heavier riders need stiffness and wide faces. Across all types, the same basics win. Clean faces, correct preload, true over-center, and steady checks. Consequently, your scooter will feel planted, quiet, and safe.